Our parent company, Chukar Culture, is selling Hells Canyon Beer “Bucking Chukar” t-shirts. We’ve sold out of three straight orders, and this is our 4th and final batch this year. Get ’em while they’re hot over at Chukar Culture!

My First Saison

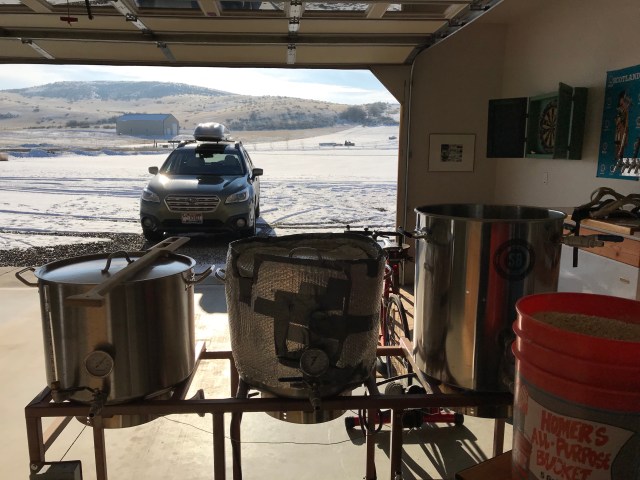

Not that the video sheds any light on brewing a saison, but that’s what I was doing. One of the big differences was the step mash instead of a single infusion, and the whole mash process took more than two hours, but aside from the yeast (Imperial’s “Rustic”) and relatively low hop bill it was pretty straightforward.

This was my 5th brew on my new system, and I’m starting to understand it, but still struggling with the cleaning process, which really extends my brew day way more than I’d like. I’ll figure it out, but am open to any ideas for curtailing the cleaning. (We are on a septic system, so I’m trying not to put a lot of junk down the drain, both in terms of hop residue or cleaning chemicals…).

Cheers!

Bucking Chukar

So, thanks in part to Covid-19, things have gotten a little out of hand in the brewery-that-used-to-be-our-garage. My lovely wife decided to get me a logo for Hells Canyon Beer as an early birthday present (possibly thinking I won’t survive until I reach my next birthday; need to check on whether she took out another life insurance policy on me). I’m into several batches now on my new Ss Brewtech 3-vessel electric system, with a NEIPA chugging away in the unitank (to be kegged as soon as I crash it with the glycol chiller that just arrived). Anyway, we’ll have some shirts and hats, and maybe pint glasses with this logo for sale on the Chukar Culture website before too long. With any luck, it’ll be before the stay-at-home directive expires (which could be years, so don’t hold your breath). Anyway, some good news, at least for us, since we think the graphic is very lovely.

Many News

New system, new beer style… I’m learning the ins and outs of the Ss Brewtech 3V system I recently acquired, and want to share a bit of my second batch experience, which was my first shot at brewing a New England IPA. Often while brewing, I’ll practice my bagpipes while waiting for the mash or the boil to finish.

This is the secret ingredient of Hells Canyon Beer. The tune I’m playing while the grain is mashing is one of my favorite piobaireachd melodies, “Nameless (Hiharin Dro O Dro),” which is appropriate for this specific beer: the beer is called “Certain Slant NEIPA (New England IPA)” which is named after one of my favorite Emily Dickinson poems, “There’s a certain slant of light.” Her poems were not titled (i.e., “nameless”), but are known from the first line of the poem. Same with this piobaireachd, which they call “Nameless,” but because there are other un-named piobaireachd tunes also called “Nameless,” they distinguish them all by putting in parentheses the vocables of the first line, in this case hiharin dro o dro, which is how you would sing the specific notes of the opening melody (as long as you know what a “hiharin” or a “dro” sound like). The beer style connects to all this: it’s a New England IPA, and Emily Dickinson lived in New England. Finally, there’s another connection, too, which has to do with the yeast: the yeast strain is London Ale (Wyeast 1318), originated in England, and — if I were to culture this for future brews — I would use certain kinds of “slants” to store the yeast for cultivation down the road. So there it is. Enjoy!

I also added a steam condenser to the boil kettle so I could brew with the garage door shut and not turn the ceiling into a gooey mess of degrading drywall. Here’s my review of the first test run on the Steam Slayer by Brewhardware.

Almost Electrified

New Spike 20-Gallon Boil Kettle

Proudly standing at attention to my new Spike 20-gallon boil kettle (but should have posed on the other side so you could see the branding; see photos below from the other side of the stand)

After numerous boil-overs in my 15-gallon pot, I finally pulled the trigger on a bigger boil kettle. After looking around for awhile, I settled on Spike Brewing‘s 20-gallon kettle. The cost, design, and features sold me, even though it’s too tall to fit below the burners for storage as my shorter 15-gallon kettles do.

When doing 10-gallon all-grain batches, the pre-boil volume is typically almost 14 gallons, which – on the 15-gallon kettle – comes to about 1/2″ below the rim. Even with a tightly controlled boil and using FermCap-S, I still suffered explosive wort eruptions on every batch. I wish I’d realized this before purchasing my kettles so I could have designed my single-tier stand to accommodate the 20-gallon kettle for storage, but I’ll find someplace for the big pot and will be much happier and cleaner on brew day. The 14-gallon mark on this new kettle is about 6-inches below the rim, so we should be safe.

Spike Brewing’s kettles have a bunch of cool features. The main one is the recessed bottom (about 3/8″) which should allow a nice hop cone to form after whirlpooling the wort, with the pickup tube resting just above the bottom level. I’ve been having lots of trouble lately with hops getting into my plate chiller and stopping the transfer from boil kettle to fermenter. This turns transfer into a crisis operation because when it clogs I have to disconnect the chiller and blow it out with hot water, leaving the connections vulnerable to cold-side contamination. I’ve used a hop cylinder in the boiler, but have read that utilization is impaired, similar to mesh hop bags, so I’m hoping to do a better job of whirlpooling the hop pellets into a clean cone; the stepped bottom design of the Spike kettle should help this.

Another cool feature, which many kettles now include, is laser-etched, graduated volume markings. Until now, I’ve used my stir paddle’s rough markings to guestimate volume. This should be more accurate and – maybe – help me do a better job hitting my numbers on brew day.

Finally, the pickup tube is a full 1/2″ and uses a “push-to-connect” fitting that threads into the bottom port. It’s angled to suck from the side just above the bottom level of the kettle. One thing I wish I’d included was another port at the top of the kettle to accommodate a recirculating whirlpool fitting; given my trouble with hops lately, I’m worried that my paddle’s work making the whirlpool might be keeping hops from settling into the cone. Time will tell. I might add a whirlpool port later if my local welder will trade for beer!

Now that I have Spike’s new boil kettle, I want a bigger mash tun!

UPDATE: So, the first brew in the new kettle went super well. The whirlpool worked to keep most of the trub in the center, I beat the OG by one point (but took 30 more minutes to do it), and the beer’s gurgling away in the fermenter. Yippee! Below are a few more photos with this new kettle in action.

Psyched to now have all these loose things corralled: plate chiller, hop rocket (which I use sometimes as a filter with rice hulls and leaf hops), and oxygen system.

Spent Grain Treats for your Best Friend

Compost? Animal Feed? We decided to use some for compost and the rest to make peanut butter dog treats for our best friend. Four simple ingredients and easy to make. Give these to your dog and if they don’t already love you they most certainly will after these drooliscious treats.

Spent Grain Dog Treats Recipe

4 cups spent grain

2 cups flour

2 large eggs

1 cup peanut butter

Directions:

Mix all ingredients together in large bowl, then roll out on flour coated surface and use cookie cutter to make desired shapes. Put onto cookie sheet and bake in 350 degree oven for 30 min. Turn treats over on cookie sheet then reduce heat to 225 degrees for 2 hrs or until dry (to prevent mold growth). Store in air tight containers. Freeze leftover treats in Ziplock bags and thaw out as needed.

Firstbrew

Long time coming, but better late than whenever. A fit of je ne sais quoi pulled the release on this and it’s on. Let’s see where it goes.

I made my first batch of beer, an extract stout from a kit, soon after turning 21 in Berkeley, California. There was a home brewing store way down on San Pablo Avenue, in El Cerrito, actually. It must have been 1983. Stovetop beer, plastic buckets, bottles everywhere, a complete mess. No clue. I wish I could remember more about it, other than I couldn’t believe how cheap it was to make my own beer, and some friends who seemed very happy to watch and help ingest the evidence. One guy, Mike, came over and saw what I was doing – boiling a batch in a cheap enamel-covered tin canning pot on the electric stove in the apartment I shared with three young women. I didn’t care for Mike much, but he wanted to learn even though he needed a few years to be legal. I showed him the steps, and forgot about it. A few months later I found myself at a party in his apartment. Eight 5-gallon plastic fermenters, festooned with bubbling airlocks, lined the hallway between the kitchen and his bathroom. Mike clearly had launched himself, found something bigger and better. It might have been envy, but regardless – at the time I thought his brewing mania broadened his idiocy. I wonder if Mike still brews.

I’ve become Mike. I wonder what’ll become of me.